Goetze® Materials

Materials

Seal rings

Wear and corrosion resistance are the two main requirements that have to be fulfilled by seal ring materials. As such, our metallurgists have developed special cast iron materials specifically for the rough working conditions that mining machines and construction machinery are exposed to.

These cast iron materials show a good corrosion resistance due to the careful selection of alloying components. They are also exceptionally resistant to abrasive wear because of their increased hardness.

In addition, we offer different coatings which provide optimum sealing solutions for higher sliding speeds, enhanced corrosion resistance for demanding environments, and reduced friction loss for higher speed applications. Please send us your specific requirements for engineering review. Duronit: The standard high performance material Duronit is very common in the cast iron seal market. This ledeburitic cast iron with fine graphit inclusions is characterized by its excellent wear resistance in combination with good tribological behavior. Even under extreme stress Duronit proves its outstanding resistance against seizure and scoring.

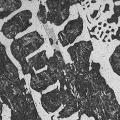

Duronit: The standard high performance material Duronit is very common in the cast iron seal market. This ledeburitic cast iron with fine graphit inclusions is characterized by its excellent wear resistance in combination with good tribological behavior. Even under extreme stress Duronit proves its outstanding resistance against seizure and scoring.

Coronit: The latest material development is the high speed material Coronit, which is also based on a ledeburitic structure in which free graphit is embedded.

Coronit: The latest material development is the high speed material Coronit, which is also based on a ledeburitic structure in which free graphit is embedded.

The successful combination shows excellent tribological characteristics and allows a sliding speed of up to 12 m/s. The reduced friction loss and efficient heat transfer provide clear advantages for face seal durability in high speed applications.

O-rings

High thermal resistance and low compression set are the essential criteria specified for the elastomer material in demanding applications.

Our standard design meets these requirements with the use of nitrile-butadiene rubber (NBR). For higher thermal stresses, the o-rings are constructed of HNBR, FPM or VMQ. The oil compatibility of several elastomers has to be checked.

The elastomer materials listed are offered in various degrees of hardness (Shore A) so that the o-ring can adequately perform its function of generating a permanent and consistent contact pressure within the sealing system.

We consider the further development of materials as an essential process to meet the increasing demands of our customers. We actively promote this development and set new standards.

For any special requirements or wishes, please contact our application engineers or development engineers to jointly find a solution.