Goetze® Applications

Application Examples

GOETZE® face seals are found wherever the going gets really tough: as seals for wheel hubs and axles, running gears, roller bearing and roller guide bearings for track laying vehicles, gearboxes and many other axle connections in heavy technical equipment such as construction machines, mining machinery, concrete and cement mixers, tunneling machines and agricultural equipment. In particular, the operation in abrasive media such as dust, sand, mud, stones, under water and soil pose extreme demands on the wear resistance of the sealing system. High-quality components such as planetary sets, brake plate, bearings and the hubs of wheel running gears or axles are better protected against the permeation from destructive media.

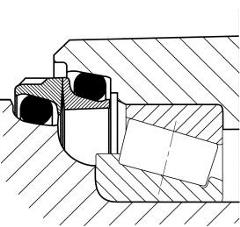

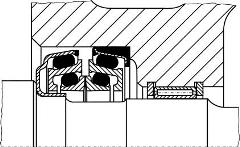

Seal for conveyor for abrasive media

Lubrication chamber sealed with radial lip seal; back surface facing lubricant to prevent pressure build-up in the sealing space.

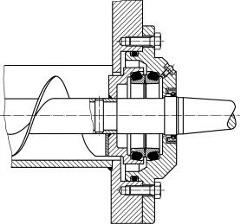

Seal for track roller of excavator

Seal for cutting shaft of crop harvester

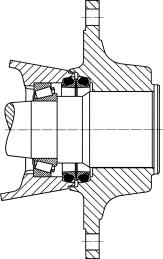

Seal for wheel bearing axle

The inner tapered ring enables the housing contour to be machined directly on the shaft.

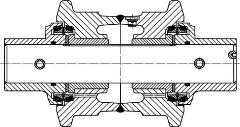

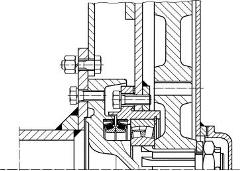

Seal for rigid axel of tractor

Seal for transmission housing

Designed with Adapter Rings type 76.91 for installation in cylindrical housing bores.

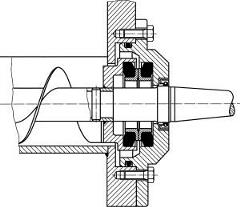

Seal for screw conveyor for abrasive materials

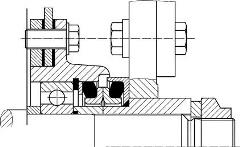

Seal for steering drive axle

Steering movements cause an axial displacement of the floating axle of about 5 mm. This movement is compensated by the double configuration of the seal.

Due to many different application possibilities and diverse application parameters, no system is like the other. For this reason, we would like to draw your attention to our decades of experience and our unique technical competence. We check individual parameters using a technical data sheet, so we are able to offer our customers the optimal solution for a consulting-intensive system.