Goetze® Face Seal Design

Design

Different operating requirements require different designs. The company's product development and application technology are bundled into one unit to provide the best possible support for customers and to offer the best individual solution - whether to adapt an existing product or to develop a new design. Based on many years of experience and expertise, GOETZE® has developed a robust analysis tool for the design of face seals. This tool makes it possible to evaluate new sealing geometries by simulation, or to find solutions for existing problems with customer applications. The virtual design is then validated by a series of laboratory and test bench trials, which include preload, spring characteristics, temperature and wear parameters. Special requirement tests, such as long-term and mud box tests, supplement validation.

Please contact our application engineers for the appropriate design. Contact Us

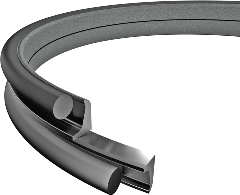

Type 76.90H/76.97H - Seal rings with o-ring

The most common design of mechanical face seals is the o-ring design. This design consists of two symmetrically tapered seal rings and two o-rings. The o-ring style has two versions, the 76.90H which has a ground profile, and the 76.97 which has an as-cast profile. In general, both versions are completely interchangeable.

The most common design of mechanical face seals is the o-ring design. This design consists of two symmetrically tapered seal rings and two o-rings. The o-ring style has two versions, the 76.90H which has a ground profile, and the 76.97 which has an as-cast profile. In general, both versions are completely interchangeable.

At installation, the o-rings are compressed between the tapered contact surfaces of the seal ring and housing. The o-rings undergo a calculated compression which is critical for proper operation of the sealing system (dimension “A”). Cleanliness of the o-rings and housing (free of oil and dirt) is of primary importance. Lubrication of the o-rings with oil or grease is not permitted during the installation process.

For detailed information please see our installation guide or ask for our assembly movie.

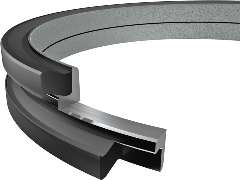

Type 76.95 - Seal rings with trapezoid ring

Type 76.95 requires slightly less installation space in the axial direction than the standard o-ring style designs (76.90H / 76.97H). The geometry of the housing contour is easier to manufacture, and the seal installation does not require an installation tool. In comparison to the o-ring face seals, the spring characteristic of the trapezoid elastomer parts is usually stiffer. This leads to a limitation of permitted axial movement and tolerance. Dimensional deviations have a negative influence on the resilience reserves.

Type 76.95 requires slightly less installation space in the axial direction than the standard o-ring style designs (76.90H / 76.97H). The geometry of the housing contour is easier to manufacture, and the seal installation does not require an installation tool. In comparison to the o-ring face seals, the spring characteristic of the trapezoid elastomer parts is usually stiffer. This leads to a limitation of permitted axial movement and tolerance. Dimensional deviations have a negative influence on the resilience reserves.

This type of seal is typically used where high torques are required due to adhesion and surface drying of dirt in order to move a machine after a standing time. It frees itself from pollution and therefore resumes its axial mobility better than the 76.90.

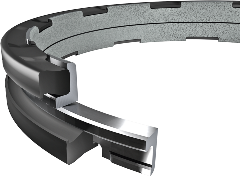

Type 76.95H - Square bore face seal with retaining lip and spin protection

This version is a further development of the standard type 76.95. The advantage of using this sealing system is the prevention of axial displacement caused by dirt-encrusted elastomer parts. Furthermore, it prevents the metal and elastomer parts from spinning at higher break-away and friction torque.

This version is a further development of the standard type 76.95. The advantage of using this sealing system is the prevention of axial displacement caused by dirt-encrusted elastomer parts. Furthermore, it prevents the metal and elastomer parts from spinning at higher break-away and friction torque.

To fulfill these requirements, a retaining lip is located on the back of the seal rings to support the trapezoid ring against axial displacement. The seal rings are also provided with pockets, which allow the elastomer parts to grip into the retaining lip in a positive-locking way.

All other features correspond to the seal type 76.95.

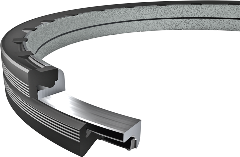

Type 76.95 - HSL square bore face seal with retaining lip, spin protection and dirt extruder lip

The most recent face seal development is the HSL seal, an evolution and special form of the company’s proven square bore seal 76.95 H. The HSL seal uses a unique and patented design for the elastomeric part of the seal with an integral dirt exclusion lip and heavy-duty spin protection. These features improve the seal performance significantly under extreme mud packing conditions. This keeps the seal fully flexible and leads to reduced leakage and extended service life.

The most recent face seal development is the HSL seal, an evolution and special form of the company’s proven square bore seal 76.95 H. The HSL seal uses a unique and patented design for the elastomeric part of the seal with an integral dirt exclusion lip and heavy-duty spin protection. These features improve the seal performance significantly under extreme mud packing conditions. This keeps the seal fully flexible and leads to reduced leakage and extended service life.

Type 76.93 - Combination of different rings

In the 60-year history of manufacturing mechanical face seals, a number of designs have been developed for specific constructional and operational situations which can in principle be used for an extended range of applications. In all cases the seal sets have performed outstandingly well in rough daily operating conditions.

In the 60-year history of manufacturing mechanical face seals, a number of designs have been developed for specific constructional and operational situations which can in principle be used for an extended range of applications. In all cases the seal sets have performed outstandingly well in rough daily operating conditions.

In particular, the inverted seal ring design provides a considerable savings potential with respect to the cross section and the manufacturing technology.

There are also special designs of the seal type 76.95 available, which have been developed specifically for applications with extreme mud impact.

We recommend contacting our engineering team if you plan to use the type 76.93 in your application.

Type 76.91 - Adapter rings

In some sealing applications, the use of the standard design 76.90H / 76.97H is more complicated because of functional, construction or production-related reasons. This is the case, when the seal type 76.90H / 76.97H is installed into cylindrical bores. The 76.91 adapter rings are an exceptional choice when a strong abrasive environment results in significant retaining lip wear on the housing contour. The 76.91 style rings eliminate the need to re-machine the housing, saving time and costs during scheduled maintenance activities.

The 76.91 adapter rings are an exceptional choice when a strong abrasive environment results in significant retaining lip wear on the housing contour. The 76.91 style rings eliminate the need to re-machine the housing, saving time and costs during scheduled maintenance activities.

The Adapter Ring, which is available in possible forms A and B, consists of deep-drawn sheet rings, which are encased in an oil-resistant elastomer material. The static sealing and transmission of torque is guaranteed by an outer wave-profile of elastomer, which also protects from corrosion.